Integrated solutions by Unimac-Gherri

The company, part of Arol Group, is specialised in the filling and capping of glass, metal and plastic containers with twist-off caps for the packaging of liquid, semi-liquid and pasty products. It offers a wide range of solutions, both turnkey lines and free-standing machines.

Unimac-Gherri, part of Arol Group, is a company specialised in the filling and capping of glass, metal and plastic containers with twist-off caps for the packaging of liquid, semi-liquid and pasty products. Today, the Emilia-based company offers a wide range of solutions, both turnkey lines and free-standing machines for food packaging lines: rinsers, fillers, capping machines, feeders and, to complete the range, palletizers and depalletizers.

Regarding this technology, Unimac-Gherri has developed a new robotic version: the UG500 robotic palletising unit. Highly flexible at work, the high-speed robot is practical for a range of logistical tasks related to end-of-line automation, and with its performance-oriented design it enables the facility to competently handle even larger and unbalanced loads, again at high speed.

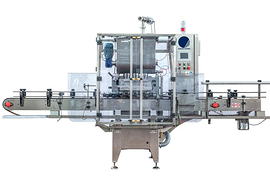

Anuga Food Tec will be an opportunity to show visitors the GG100 automatic linear capping machine: a model that can have all the necessary equipment to cap Twist-off, Pry-Twist and Pry-off caps of all sizes - regular, medium, large - with a maximum speed of 12,000 BPH. The capping activity of this machine takes place in a steam-saturated chamber with a high vacuum level inside the container that remains constant, while the formats can be adjusted without the use of special equipment, even with the machine in production. Its change format is quick and corrosion resistance is guaranteed.

Finally, the capper is provided complete with a magnetic feeder, model GG850, suitable for sorting and feeding caps into the hopper to the capping machines, with a speed of up to 200 BPM.

Another solution on stage at Anuga Food Tec will be the PF3T linear filling machine. This model is suitable for filling viscous and semi-viscous products such as: tomato paste, ketchup, vegetable-based sauces, various kinds of sauces, jam and jellies, spreadable creams, honey, baby-food and similar. Its special feature is that it is a highly flexible and versatile solution. It is capable of filling 20ml singledose products – with piston/ double cylinder filling unit - up to 5kg containers. Format change is simple and user-friendly thanks to the recipes that can be set on the control panel.

Anuga FoodTec 2024

Hall 7.1 – Stand E010 F011

Prodotti e tecnologie: AROL

Gallery