Pet Food Competence Network to get to market faster and smarter!

Wim Kruikemeijer, Group Coordinator Pet Food Competence Network, speaks about a group of like-minded companies, with decades of combined experience, able to create synergies in order to give simple and streamlined access to the very latest technologies for the pet food industry. All of which can be tailored, developed, scaled and installed to match customers’ precise needs.

Can you talk about the Pet Food Competence Network and its goals?

The existence of the PCN came from troubles that Cama, as an end line manufacturer, was continually forced to face. If something upstream was not correct, we ran the risk of compromising the efficiency of our products as well. What I wanted to learn is what we as Cama should take into account from upstream suppliers in our systems. And, the other way round, what can I tell upstream and downstream suppliers about our processes and what’s important for our processes. So, I and my network decided to put our minds and our know how together in order to avoid making the same mistakes time and time again and before we knew we were 12 companies. Today we are working together on projecting, we are helping each other when we see that mistakes are made at our customers’ companies. Moreover, we are also innovating in order to reply our customers’ needs and we can do that because of our group’s know how and because the pet food sector is very dynamic, not only from a marketing point of view but also in terms of ingredients. The market is constantly changing; pets are more and more members of our families and are treated that way. A lot of benefits come out from this cooperation.

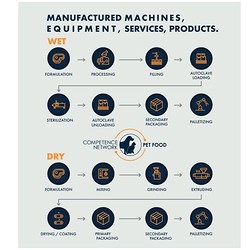

Are the companies, members of the PCN, able to support pet food industries at every stage of the production process? Each company in the network brings its own domain expertise and extensive industry R&D experiences. In this sense, how are you able to create synergies?

We start from the very beginning, and beginning is the formulation of pet food, which is very important in order to come to a quality product and a stable and constant process, especially when you work with natural ingredients. This is affecting the quality of the food but it isn’t limited to that, it is also affecting the handling and the packaging process. Synergies are very important because all the processes are connected to each other. The synergy is very simple in order to define what we expect from each other, what is a good product and what is not a good product. This is very important in order to create a stable process for our customers. Of course, the synergy also includes innovation.

In terms of technology integration, what are the advantages of a unique suppliers’ network?

There are a lot of advantages. First of all, we all have experience in the pet food sector, which is completely different than the human food sector. Secondly, we know the markets and altogether we know a lot more than acting as individuals, so we can advice our customers about which will be the future market trends.

Sustainability is one of the main drivers that the pet food industry is looking to achieve. What are the main challenges in this field?

There are two main challenges. Fist of all, and that is the most important one in my perspective is to avoid waste because food waste has a much bigger environmental footprint than a monomaterial packaging, which is also important. Sometimes it’s even better to use more packaging material or a packaging material with a longer shelf life in order to avoid food waste. So, the first one is to avoid food waste using the correct packaging material but also by making sure that the customer can have a vertical start up. Secondly, materials. So, what to do with replacing laminated films with monomaterial film, what is the optimum that we can achieve together. Shortening the shelf life in order to use a monomaterial isn’t always the best option. Maybe you have to choose something completely different. This is very interesting too, we want to avoid that you make the wrong choice.

What kind of strategies, procedures, practices and technologies have you developed and adopted to make processes more sustainable, as well as final products?

If I talk about our equipment, we help our customers operate the machines how they should be operated by Industry 4.0 applications. This is positively influencing a vertical start up, for example after a changeover. So, in this way we can avoid food waste. This is what we are working on. And of course in the processing it is very important to save energy because a lot of energy is involved in this.

In this moment, what are the main requests of pet food industries? How can the PCN reply?

The market is moving very quickly, it’s a very agile market, what our customers are asking is “how can we keep up with this market?” and “what can you recommend to fulfill our customers’ needs?” Now we see that pet food customers are more environmentally connected than the others because they like animals and they feel the responsibility of a green world. This means, for example, that our customers want to reduce their packaging material and, on the other hand, they want to maintain the quality. This is a three way street: we are working with retailers, our customers (pet food producers) and our peers in order to see how we can reach our goals in a holistic way with all our colleagues in the PCN in order to offer the customers of our customers a good customer experience, for example with single-serve but in a green way, and still make a product which is affordable. In the pet food market food safety is very high because ingredients are very sensible for bacteria. For example, if we talk about wet pet food in pouch, we used to work with a quarantine in order to ensure that only good products would leave the factory. Today, we can pack directly into the shipping case just after the sterilizing and drying, so we don’t need the quarantine anymore because we have improved our processes and our detection systems. All the storage and the handling is not necessary anymore. It is important that large companies see working with us as a very good opportunity to start a green field from zero. We are able to support them since the very beginning. We have consultant ready to instruct, inform and prepare the company for a new business. Pet food is a very rich market, so companies could think about opening new pet food factories as an investment. So it is important to have a network, not only as a machine seller but also as a partner, in order to start a new journey.

Gallery