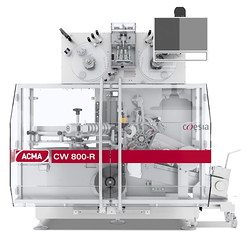

ACMA, ninety-five years of innovation and tradition

The guiding principle of innovation has never been broken and has led the company to span the decades by consistently offering cutting-edge solutions. This has positioned it in the confectionery and other markets as a leading player and an expert partner in the quest for solutions to meet the needs of customers.

At Cologne ACMA will be presenting its new operator panel (Web HMI), a revolutionary approach to machine interaction and management. The new panel guides the user through all operations in an intuitive and user-friendly way, from day-to-day machine operation to maintenance and format changeover. It allows for real-time intervention (Advanced Remote Assistance) by ACMA’s team of experts to perform diagnostics and fast troubleshooting. In addition, it constantly monitors the machine’s operational parameters to optimize the production flow settings, ensuring maximum efficiency and keeping downtimes to a minimum.

For ACMA, “innovation” means not only “performance” but also the pursuit of efficiency. One of its fundamental rules is to develop cost-effective solutions in terms of both energy consumption and environmental impact. For this reason special attention will be paid during the event to developments within the world of packaging that relate to materials and sustainability.

Through its synergy with the Coesia Group, particularly in the research and testing of innovative technologies and materials, ACMA positions itself as a leading partner in the creation and handling of special shapes to distinguish products on the market. Perfect, cutting-edge technological integration to ensure maximum market success.

In Cologne ACMA will be co-exhibiting alongside XPack, a company specialised in the development of wrapping machines mainly for the confectionery sector. XPack offers solutions that respond to differing production and financial needs in the market, handling products with a combination of flexibility and quality. As well as chocolate wrapping machines XPack has also, over the years, developed individual projects for the soap and coffee markets, thus highlighting the company’s engineering versatility.

HALL 10.1 – STAND G40/H41