Cama Group, robotics designed for packaging

1989: The dawn of Cama’s robotic expertise and the food industry’s renaissance.

Cama Group has been producing robotised systems since the end of the 1980s, when its founder, Paolo Bellante, designed and produced the company’s first industrial robots for the bakery sector, which even back then required high production capacities.

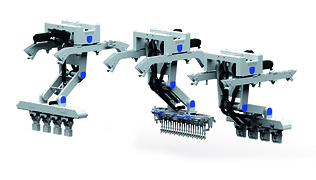

“Our first two-axis robot, the Cama RB 504, proved a revelation in the food product packaging sector thanks to its cutting-edge innovation; and it saw wide adoption across the world,” explains Annalisa Bellante, joint owner of the Cama Group.

Following these early successes, Cama established its own distinctive concept: integrated multi-purpose robots that are specifically adapted to the needs and characteristics required by the packaging sector. In-house development, tuned to the needs of the eventual end users, also means the company delivers robotic control from the machine’s PLC, rather than relying on proprietary ‘black-box’ controllers running on bespoke, isolated software.

The use of robotics also fostered new approaches in the packaging sector, such as pick-and-place simulation of the work carried out by human operators.

This revolutionised the development of automation processes in large food production companies across the world.

With the market’s continued and growing requirement for increasingly flexible and agile packaging systems, Cama continued to develop new robotised applications. The end of the 1990s saw the first in-house developed advanced four-axis robot models, which could be tightly integrated into packaging systems including the company’s own high-speed continuous motion machines.

In the early 2000s, backed by highly successful collaborations with research bodies and universities and significant internal investment, Cama delivered its next major breakthrough to the food sector.

“In 2007, Cama completed its range with the production of its first four-axis delta robot. Fully and tightly integrated into the company’s machines – in terms of mechanics, electrics and software – the turnkey solutions delivered by this combination of technologies proved immensely popular in the market, thanks to Cama’s ability to tailor performance to the precise needs of an application – something our strategy has always involved,” continues Annalisa Bellante.

By 2010, thanks to its strengthened internal Robotic Division, Cama had cemented its position as a multinational company in the robotic automation sector for the food production industry – thanks to its ability to design and produce robots dedicated to specific applications.

The company’s 100+ patents, reinforces its intense and constant activity in research and development, with a focus on three types of robotic applications: two-axis robots, with fixed or movable pivot pins; and delta robots, combined with advanced monitoring systems for packaging products that are loose or those that come in more than one flavour.

“Since the 1980s, Cama has come a long way in the development of robotic applications for the packaging industry… and generally in regards automation for the food & beverage industry. And now, in the present day, with the current COVID-19 crisis, we need to look more than ever at the organisation of both companies and their production processes to ensure maximum flexibility and longevity. Over the course of the next few years, the field of automation will undergo significant development and there will be an extensive review of where and how the industry works,” Annalisa Bellante concludes. “And you will see Cama, at the front of the pack, leading the way, delivering the very latest technology industry has to offer!”

In the opening picture: RB 504, the first 2 axis robot, 1988

Read the article on Rassegna dell’Imballaggio International Issue

Prodotti e tecnologie: CAMA GROUP

Gallery