Herma, when robots label with greater efficiency

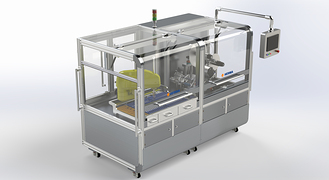

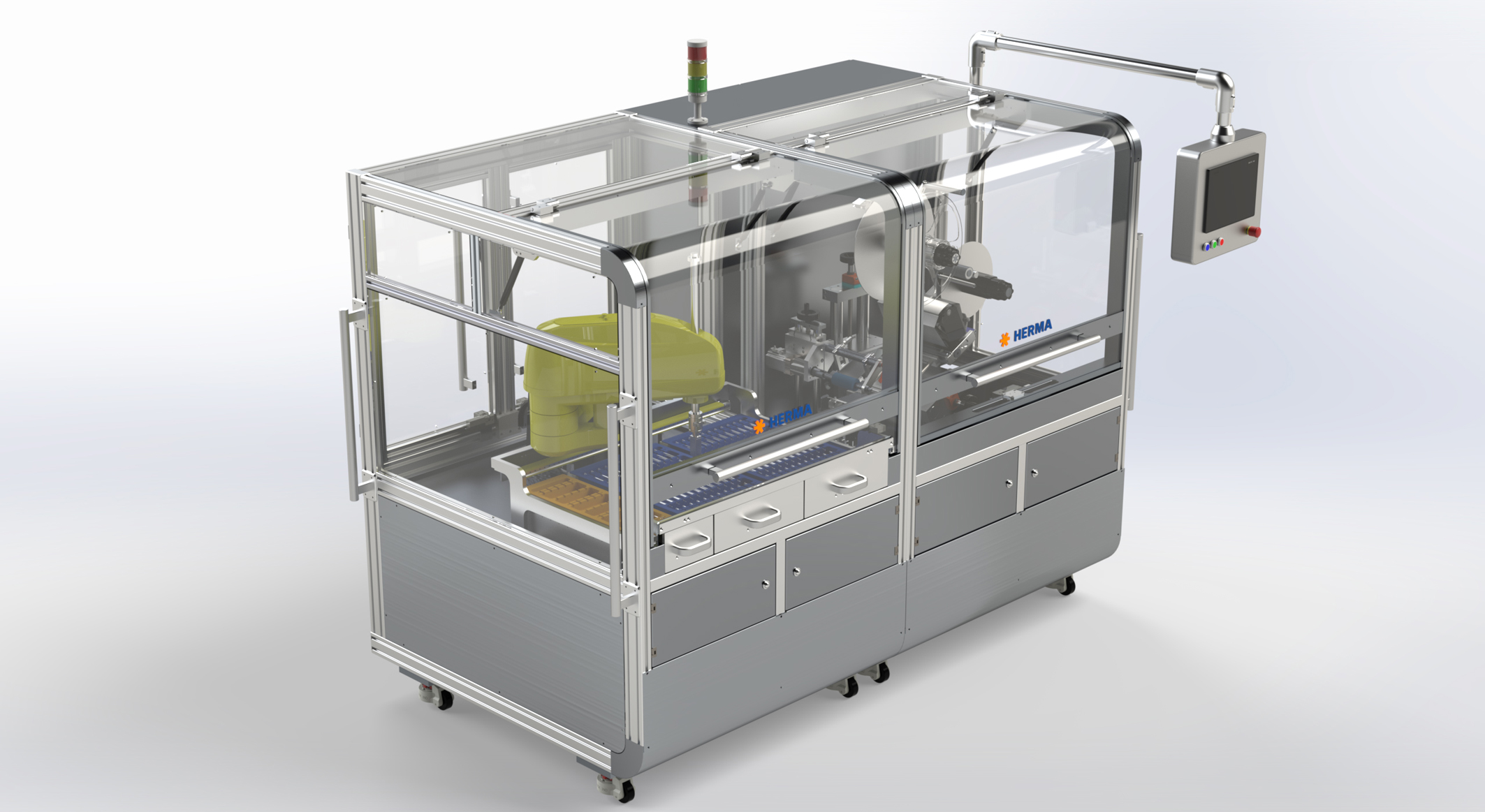

During Achema, Herma will showcase the 211 HC RC, its first robotics-assisted labeling cell for wraparound labeling. It labels around 20 products per minute and is therefore about 25 percent faster than a comparable semi-automatic labeling machine without robotic assistance.

At ACHEMA 2024, HERMA will demonstrate to visitors how robotics make challenging labeling processes more reliable, more cost-efficient and faster.

Ideal robot for pharmaceutical products

The specialist for packaging and product labeling will showcase the 211 HC RC, its first robotics-assisted labeling cell for wrap-around labeling. The labeling cell is specially designed for pharmaceutical products such as small vials, pens, syringes and carpules. Until now, small batches of such products were labeled mostly by semi-automatic labeling machines. This required labor-intensive, manual feeding and removal of individual products, which were frequently prone to a degree of error. For example, the operator could mistakenly place an incorrectly labeled product in the tray containing correctly labeled products.

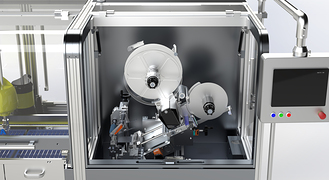

With the 211 HC RC, operators can effortlessly streamline their workflow. Using an intuitive drawer system, unlabeled products can be placed directly into trays within the closed labeling system eliminating the need to open the safety cover. This innovative approach not only enhances efficiencies but also prioritizes safety, ensuring smooth operations with minimal disruption. The robot removes the products from the tray and deposits them precisely in the labeling station, which is equipped with a HERMA 500 label applicator. After the labeling operation, the robot places the labeled products under an image processing system or a sensor to check that the labels and the required variable data are present. Any confirmed products are placed into the tray or cartons provided; unconfirmed products are placed into a separate tray.

Gateway to continuous production

The 211 HC RC labels around 20 products per minute and is therefore about 25 percent faster than a comparable semi-automatic labeling machine without robotic assistance, all this without any loss of concentration over longer periods, even in the case of continuous production.

A further advantage in addition to the increase in performance: “By automating the entire labeling process, we significantly reduce the risk of human error associated with manual labeling tasks,” says Gary Hopkins, the specialist responsible for robotics at HERMA. “This in turn reduces the risk of product recalls”.

There is also an important compliance aspect: The robotic labeling cell can be programmed so that it automatically complies with certain labeling regulations and standards. This ensures that all products are always labeled in accordance with the applicable statutory provisions. The versatility of this labeling cell arises from its wide range of possible configurations, enabling the application of various label types and the printing of variable data such as barcodes, serial numbers and expiry dates. In addition, the 211 HC RC can be optionally equipped with commonly used hot-foil, thermal-transfer and laser printers. Thanks to its simple scalability, it can be quickly adapted to tomorrow’s requirements and is therefore particularly future-proof.

“In view of the growing shortage of skilled personnel and increasing labor costs, the integration of robots in machines is becoming a cost-efficient solution to maintain and boost productivity,” stresses Gary Hopkins. “This is why HERMA is increasingly looking to robotics to offer our customers highly automated solutions that not only meet today’s demands, but are also flexible enough to allow for future requirements”.

Achema 2024

Hall 4.1 Booth B20

Prodotti e tecnologie: HERMA

Gallery