Pharmaceutical vials labelling by Etipack

Top level performance in the application and control of self-adhesive labels on cylindrical bottles. This is the promise of the new automatic labelling system Pharma Round, the high-end protagonist of the Etipack Pharma project.

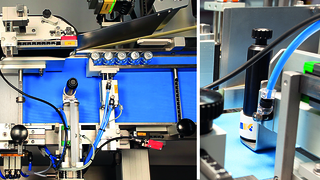

Efficiency, control and design are the distinctive features that distinguish Pharma Round as the perfect synthesis between ergonomics and performance. Conceived according to GMP guidelines and specific for the pharmaceutical environment, for functionality and technical characteristics Pharma Round is the top of the line for the labelling of cylindrical pharmaceutical products.

In order to offer high accessibility, the system is equipped with a special labeller with frontal reel loading on the operator’s side that facilitates management, inspection and maintenance operations. The control panel with fail-safe PLC electronics, for the constant diagnosis of the peripherals according to the pharmaceutical sector specifications, and the system management through HMI operator panel – with 12-inch touch screen panel PC, SCADA software and embedded Windows 7/32 operating system – enhance further usability and reliability.

Manufactured according to the FDA reference regulations “CFR21 part11” and GAMP guidelines, the HMI panel is controlled by a UPS system to ensure the correct management of the automatic shutdown in case of power failure. The software not only allows the configuration and programming of the system but also tracks and records all operator activities and system behaviour on an SQL Express database. It is, therefore, possible to check or request the production report in PDF format, the operators’ activities, the history of electronic records, the recording of all events such as alarms, anomalies, machine stops, machine statuses, both during the processing of the production batch as well as during setup or maintenance.

Pharma Round offers high standards for labelling management. It features a station for labelling control with luminescence photocells or cameras that can be further enhanced by installing options with increasing levels of sophistication, such as overprinting control, OCV/OCR, barcode and ultrasonic photostop for transparent labels.

Another strong point is the advanced rejects handling. The system is equipped with an air-jet station that expels the wrong products into the appropriate container and a control device that certifies that the rejection has taken place. In order to increase efficiency, it is possible to integrate a label rejection mechanism that prevents the incorrect application of labels in advance, preserving the product and optimizing the operator’s activity, who can replace the vial back in line without wasting time in label removal operations. The level of quality is also further ensured thanks to good product control placed at the outlet.

Versatile also in terms of printing options, Pharma Round can satisfy different needs being predisposed to integrate different thermal ink jet or thermal transfer printing units according to the specifications required by the project.

The system is one of the new highlight of the Etipack Pharma line which includes the complete range of labelling machines and systems for the pharmaceutical sector, designed for serialization and traceability processes, which stands out for its high quality, productivity and safety standards.

Prodotti e tecnologie: ETIPACK

Gallery