The confectionery packaging by Cama Group

“This new approach has allowed us to make a difference with regard to the competition”, said Annalisa Bellante, co-owner of Cama. “Our concept of integrated modular design is so incredibly flexible that it can adapt to many different applications in the food and non-food industry”.

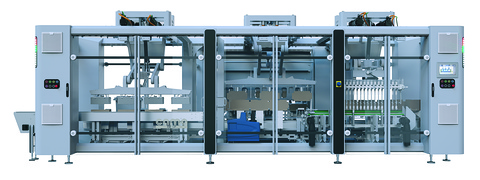

The machine that Cama is exhibiting at ProSweets is set up for the packing of flowpacked bars, showcasing Cama new, heavier duty, faster robots.

The machine also gained an award for innovation at Interpack 2017, with judges having praised its focus on changeover times with tool-less changeovers.

The IF318 includes Cama i-Track flexible pitch-less system, programmable at every stage, from carton erection, product loading and carton closing.

The IF318 also features an advanced upgraded robotics and the system ‘digital twin’, industry 4.0 solution that allows higher levels of efficiency and performance monitoring.

There are several fundamental elements of the machine; among them:

- BT generation frameworks, with higher level of hygienic design;

- an integrated cable routing system, with open framework design;

- a higher level electronic control platform, with compact electrical/control panels, for shorter start-up times and benefits for transportation.

HALL 10.1 – STAND F008