The IMA Group at ALL4PACK EMBALLAGE PARIS

The IMA Group is thrilled to participate in the 2024 edition of ALL4PACK, showcasing a comprehensive selection of technologies that span the entire production process, from formulation to final packaging.

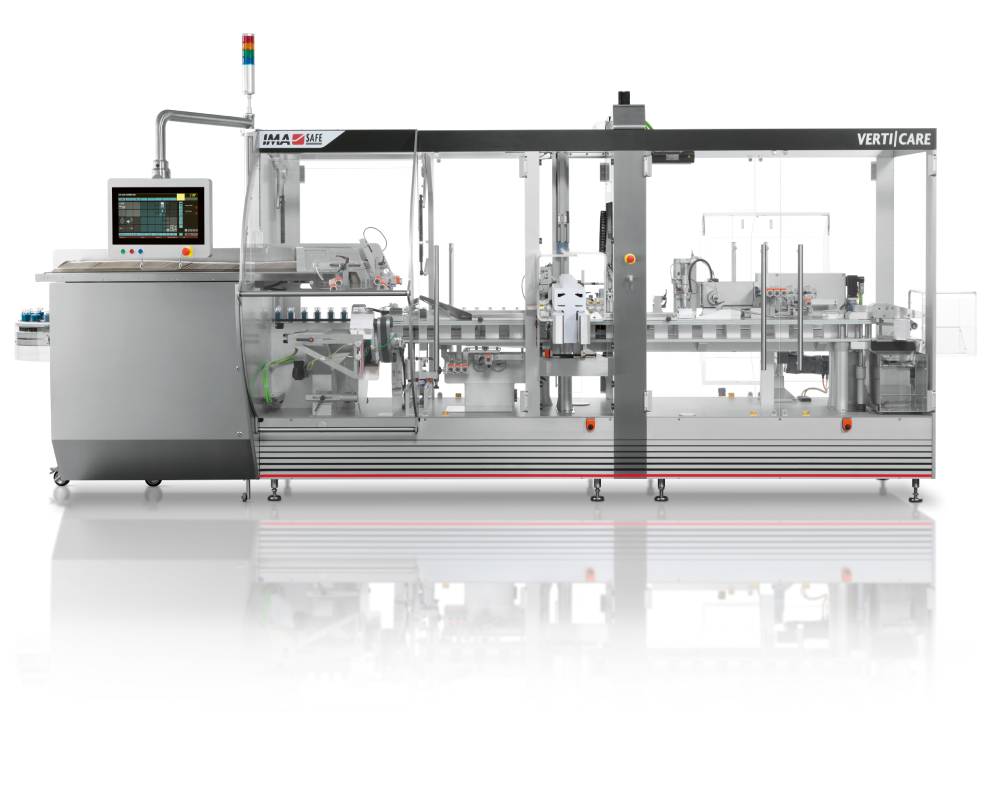

For the pharmaceutical sector, the PREXIMA 300 tablet press will be on display, representing IMA's leadership in Pharma solutions. Additionally, IMA will highlight its innovations for the Personal Care, Home Care and Toiletry sectors with the TURBOMIX CX-10 for mixing and emulsifying, the GP-500 monoblock for filling and capping, and the VERTICARE vertical cartoner, all designed to ensure flexibility, quality, and efficiency. These solutions, together with the HYWRAP20 overwrapping machine, illustrate IMA’s commitment to offering cutting-edge technologies across both the Pharma and Personal Care markets.

Powered by IMA Active’s knowledge of the sector, designed with unique Italian style, built to deliver top-level performance, PREXIMA drives productivity to a higher level of efficiency. PREXIMA ensures optimal performance even with the most difficult-to-manage powders, keeping the tablet uniform in terms of weight and hardness. Smart design leads on to great accessibility: available in three models, PREXIMA is the best solution to handle all production volumes.

Omas Tecnosistemi will be on show with the GP-500 automatic single pitch filling and capping puck monoblock, with alternate step, from an extremely dynamic and flexible concept, the ideal solution for multiple format change. It is suitable for unstable bottles and holders or for the ones with features which need the transfer into godets. Built with high quality standards, with a machine design of easy cleaning and maintenance. It guarantees extreme flexibility, adapting to every need for the dosing of products both liquid and creamy (even with hot temperature), or powders. All the parts in touch with the product are realized in INOX steel 316L or in approved FDA material. Moreover, it is possible to arrange the loading of bottles from robot, depucker for bottles unloading and godets recovery, installation of laminar flow and other options available upon request.

The TURBOMIX CX-10, part of the TURBOMIX Series by Omas Tecnosistemi, offers advanced mixing and emulsifying capabilities, user high shear energy and vacuum conditions to create fine emulsions, resulting in smooth and homogeneous creams that meet the highest quality standards. This versatile machine is ideal for producing high-quality emulsions and mixtures, catering to a range of industries and applications. The machine is designed for flexibility in formulation and high efficiency in production. Tank size: from 3 litres to 5000 litres. Further sizes and accessories available on demand.

The VERTICARE vertical cartoner, also on display at the IMA booth, represents an advanced solution for the packaging of products such as perfumes, cream jars, and lotion bottles, including those with irregular shapes. This modular machine ensures smooth and gentle processing even for highly fragile products, thanks to its innovative handling devices. Equipped with multiple feeders for items like liners, booklets, sachets, and accessories, VERTICARE offers maximum flexibility in product presentation. The cartons are transported by conveyor belts, which preserve the aesthetic quality of the packaging, while the chain-free design ensures quiet, lubrication-free operation. Capable of running with intermittent or continuous motion, VERTICARE reaches speeds of up to 120 cartons per minute and includes a bypass function for seamless product transfer to end-of-line machines, ensuring efficiency and top-tier packaging quality.

Designed to maximize efficiency for high-speed productivity and excellent packaging, the HYWRAP20 high-speed overwrapping machine ensures ease of use and total access to all machine operations. Suitable for single or bundled products, HYWRAP20 has been conceived as a hybrid solution capable of switching from film to paper without size changeover. Its compact footprint and cantilever structure allow for accessibility and ease of maintenance. Servomotors are all placed on the back of the machine and movements are electronically driven by their own specific brushless motor for accurate performance at high speed. The size changeover is very quick and requires only a few adjustments.

The IMA Group is ready to let visitors see first-hand what the “Let’s care together” campaign is all about, underlining IMA’s commitment to the Personal Care sector, where the Group is present since a long time offering complete, innovative packaging and processing technologies that ensure a high-quality finished product and effective protection throughout the production cycle, focusing at the same time on aesthetic quality and attention to detail.

ALL4PACK EMBALLAGE PARIS

Hall 5A Booth E027

PREXIMA 300

GP-500

VERTICARE

HYWRAP20

Evento: All4Pack

Gallery