Cama Group for bakery industry: flow wrapped biscuits into cartons

Cama has proven know-how within the bakery and biscuit sectors, with hundreds of successful lines installed worldwide. A recently delivered Cama line for a long established and prestigious company, well known for its wide product range, has enabled the customer to increase output whilst also improve its flexibility to meet ever demanding customer requirements.

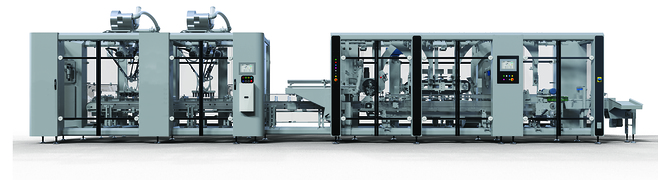

The secondary packaging line supplied by Cama has been engineered for flow wrapped biscuits, coming from two upstream flow-wrapping machines at 360 ppm. The system consists of a loading unit with two Cama Triaflex Delta robots feeding a CL series high speed continuous motion side-load cartoner.

This combined system has been designed to meet the Customer’s demands for flexibility – ability to handle a variety of products and packaging configurations; production efficiency – through guaranteed machinery uptime; and ease of use – through quick and easy size changing procedures.

This versatile Cama packaging system receives the flowpacks from the upstream equipment which are accurately metered into a multiple pocket vertical racetrack, from which the Triaflex robots pick a group of collated products depending on the format to be packed. The collation is then placed into the continuously moving bucket chain in the relevant orientation. The flexibility of the robot loading solution allows for the products to be grouped, rotated and/or stacked in different loading patterns, giving the possibility to produce multiple different formats with minimal change parts.

Once the required collation is made in the bucket chain, this passes to continuous motion side loading section of the machine, where the products are positively transferred into pre-glued cartons using an over-head mounted pusher system. Cama’s standard productivity features such – no product, no carton; pusher overload protection; open flap detect and reject; all contribute to maximize output for the customer. Production speed varies according to the product configuration, ranging from 60 to 110 ppm in this application with the CL series machine capable of in excess of 300 ppm for the relevant configuration.

This high output line is another installation that has been designed and realized according to Cama’s latest Break-Through Generation (BTG) of packaging systems. All of Cama’s new BTG systems incorporate the latest advances in packaging R&D for the secondary packaging machinery market. Cama’s innovative technology defines a new standard in the world of secondary packaging for paperboard or corrugated packaging machinery with improvements in all areas of machinery design and implementation including: improved hygiene; easier cleaning; accessibility; modularity; operability; zero retention; open profile; ergonomic access; energy saving engineering; cabinet free technology; user friendly controls and graphical interfaces for data and performance. Such characteristics are standard on the full range of Cama machines and systems.

Prodotti e tecnologie: CAMA GROUP

Gallery