igus, hygienic automation without lubricants

The company is developing lubricationfree components made of high-performance plastics for food technology. With its low-cost automation range and the robotics marketplace RBTX, it enables even the smallest companies to get started with automation.

To prevent increasing automation from becoming a hygiene risk, Cologne-based company igus is developing lubricationfree components made of high-performance plastics for food technology. And with its low-cost automation range and the robotics marketplace RBTX, it enables even the smallest companies to get started with automation in a barrier-free and cost-effective way based on the plug-and-play principle. Also the food industry, which is traditionally characterised by many small and mediumsized enterprises is also increasingly experimenting with automation and robotics to improve productivity and saving on personnel, particularly for monotonous tasks. And most of them want to invest further in automation.

“We are seeing a growing demand for components for adjustment and positioning tasks in machines, systems and robots for food technology - from plain bearings and linear guides to energy chains,” confirms Lars Braun, Head of Industry Management Food and Packaging Technology at igus. “Virtually all design engineers are looking for components that improve the hygiene of machines and systems, increase reliability and reduce maintenance work. We were able to recognise the start of this trend some time ago with the increased demand for automated format adjustment solutions.”

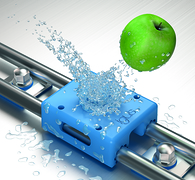

Improve hygiene, increase reliability, reduce maintenance work: to achieve these goals, igus replaces metal with high-performance plastic. Among other things, the company develops polymer components specifically for food technology that are approved for direct contact with food in accordance with the guidelines of the US Food and Drug Administration (FDA) and EU 10/2011. These include, for example, plain bearings, ball bearings and the igubal Food Contact (FC) spherical plain bearing system, which can be found worldwide in processing and packaging systems in the food and beverage industry.

Moreover, the igus food technology portfolio includes also other components for moving applications that do not require lubricants and ensure even greater food safety thanks to hygienic design. For example, an iglidur PRT slewing ring bearing, the e-chain TH3 or drylin linear guides for food contact. The shape of these components follows the guidelines of the European Hygienic Engineering and Design (EHEDG). The primary aim is to minimise the surface area for bacteria and enable easy and efficient cleaning. In addition, igus offers companies of all sizes the opportunity to put together cost-effective automation solutions on their own without any prior knowledge of design engineering. This is where RBTX.com comes in: a onestop shopping solution for low-cost robotics. In addition to igus robots such as the ReBeL Cobot, the robolink articulated arm robot or Delta, gantry and SCARA robots, interested parties will find coordinated robotics components from over 100 leading manufacturers.

Anuga FoodTec 2024

Hall 8.1 – Stand D080

Gallery