IMA Coffee Hub driving innovation in coffee processing and packaging industry

At HOSTMilano 2025 IMA Coffee Hub proudly announces the launch of a comprehensive lineup of innovative solutions designed to meet the evolving needs of the coffee industry.

Across the coffee supply chain, companies of all sizes are intensifying their commitment to sustainability. From local micro-roasteries to global producers, the industry is increasingly integrating environmental responsibility into core operations. IMA Coffee Hub stands at the forefront of this transformation, leveraging cutting-edge technologies in roasting and packaging to boost energy efficiency and digital optimisation without compromising quality.

"Today, quality, sustainability, and traceability are no longer optional — they are foundational pillars of modern coffee production," says Nicola Panzani, CEO of IMA Petroncini and Commercial Director of IMA Coffee Hub. "Digitalisation enables data-driven efficiency, while eco-design and sustainable packaging drive long-term value. At IMA Coffee Hub, we support producers of all sizes with flexible, future-ready technologies."

At HOSTMilano 2025 - Hall 18 - Booth A24 A32 B23 B31 - IMA Coffee Hub proudly announces the launch of a comprehensive lineup of innovative solutions designed to meet the evolving needs of the coffee industry.

From energy-saving roasting to precision grinding and sustainable packaging, every technology on display reflects IMA's commitment to environmental stewardship, digital transformation, and production excellence.

TTR25 EVO – Hot-Air Recirculation Roaster with Eco-Design Principles

A highlight of IMA’s roasting innovations, the new TTR25 EVO features a hot-air recirculation system and an eco-design approach that maximises thermal efficiency and minimises energy consumption. Developed with durable, recyclable materials and a modular structure, the TTR25 EVO ensures streamlined maintenance and a longer lifecycle.

Thermodynamic optimisation is central to the TTR25 EVO’s design: advanced insulation materials and strategically channelled airflow ensure uniform heat distribution, resulting in consistent roasting profiles and product quality. By minimising heat loss and optimising combustion efficiency, the TTR25 EVO achieves substantial energy savings and a reduction in CO₂ emissions.

Additionally, the roaster is equipped with integrated sensors and digital control systems, enabling precise monitoring of roasting parameters and facilitating data-driven process optimisation. This connectivity supports producers in implementing quality control protocols and traceability measures crucial for modern sustainable coffee production.

Enhanced insulation and optimised heat flows allow for significant energy savings during the roasting cycle, without compromising final product quality. This makes the TTR25 EVO ideal for roasteries looking to align with circular economy goals and reduce their carbon footprint.

XTREME GRIND – Modular Multistage Roll Grinder for Consistent Quality

IMA’s XTREME GRIND is a three-stage modular industrial coffee grinder developed to ensure granulometric precision, productivity, and long-term consistency.

IMA’s XTREME GRIND represents the latest advancement in industrial coffee grinding technology, designed to meet the demanding needs of high-volume coffee producers who prioritize both precision and scalability. This modular multistage roller grinder enables an unprecedented level of control over particle size distribution, critical for ensuring consistent flavour extraction and product uniformity across batches.

The grinder features three grinding stages, each optimised to reduce fines and maintain uniform particle size, significantly enhancing the stability of the coffee's flavour profile.

With advanced automation, servo-motor control, and recipe-based settings, XTREME GRIND supports high-capacity grinding with full flexibility and repeatability. Its modular design, integrated with an intuitive user interface, facilitates easy configuration and maintenance, while precise control of particle size ensures optimal extraction across different brewing methods.

XTREME GRIND delivers premium quality with high operational efficiency, becoming a benchmark in industrial coffee grinding.

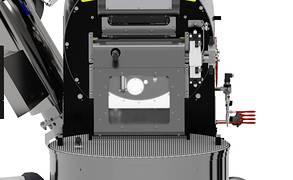

CE1 – Compact, High-Speed Paper Pod Packaging with Unmatched Precision

Designed to combine high output with a minimal footprint, the CE1 is IMA Coffee’s newest solution for paper hard pod packaging, engineered to deliver both performance and sustainability. With a production capacity of up to 450 pods per minute, the CE1 stands out for its remarkable speed, extremely compact design, and mechanical reliability, making it ideal for fast-paced, space-constrained production environments.

Its servo-driven dosing unit ensures accurate and repeatable filling, while the rotating cutting system guarantees clean, consistent pod profiles, optimising sealing and aesthetic quality. Special attention has been given to the compaction phase, enabling the production of pods with high density and uniform shape, which is essential for optimal extraction and packaging stability.

Fully compatible with compostable filter paper and sustainable packaging materials, the CE1 represents a new standard in eco-friendly, high-speed pod production — combining efficiency, precision, and reduced environmental impact.

The CE1 will be available for virtual viewing throughout the exhibition in line with CPVU, the new IMA’s advanced vertical case packer, developed to meet the coffee industry’s most demanding end-of-line requirement, for a complete turnkey pod packaging line.

CA3 – Flagship Pod Packaging for Soft and Hard Pods

Also on display, the CA3 represents the pinnacle of IMA Coffee’s technology for soft and hard paper pods. Designed for high-volume production, CA3 combines flexibility and performance with advanced process control, ensuring the highest standards in soft and hard pod packaging.

The machine accommodates different pod formats and sustainable materials for the outer envelope, enabling top performance across evolving market demands.

TWINPRO – all-in-one grinding and packaging system for R&D purposes and small-scale capsule production

IMA Coffee Hub will also present TWINPRO, the unique system that integrates the IMA’s know-how for grinding and packaging processes for small productions capacities, leading to no less than a tailor-made solution for small coffee capsule producers. TWINPRO allows for manual micrometric adjustment of the granulometry and quick changeovers of capsule formats and materials, enabling the testing of the optimal product brew, capsule configuration and material compatibility.

Developed in collaboration with the IMA Open Lab – the Group’s network of technological laboratories and testing areas dedicated to sustainable innovation – TWINPRO is the ideal tool for laboratories and R&D centres developing eco-compatible capsule systems, supporting the transition toward compostable and recyclable alternatives.

At IMA OPENLab corner at HOSTMilano, customers and partners will have the chance to start new projects and explore innovative solutions for sustainable coffee processing and packaging. Join us at HOSTMilano and discover how OPENLab turns ideas into reality.

IMA END OF LINE Hub

At HOSTMilano 2025, IMA Coffee Hub’s expertise will be complemented by the full spectrum of advanced technologies from the IMA End of Line Hub, offering a complete solution package. This includes state-of-the-art systems for manipulation, cartoning, overwrapping, case packing, stretch banding, shrink wrapping, palletizing, depalletizing, and labelling — ensuring seamless integration across the entire coffee production and packaging workflow.

Through these innovations, IMA Coffee Hub reaffirms its commitment to building a more resilient, digital, and sustainable coffee industry. Each machine reflects a broader strategy: reducing waste, increasing efficiency, and delivering premium product quality while enabling customers to meet rising sustainability standards.

Discover IMA Sentinel at HOSTMilano

IMA Sentinel is the digital platform designed to take your production to the next level. By combining real-time monitoring, predictive maintenance, and advanced AI analytics, Sentinel turns machine data into actionable insights, ensuring maximum efficiency, uptime, and sustainability. Visit us at HOSTMilano and experience firsthand how digital innovation can transform the coffee processing industry.

IMA at HOSTMilano

Hall 18 Booth A24-A32-B23-B31

Prodotti e tecnologie: IMA-INDUSTRIA MACCHINE AUTOMATICHE

Gallery