MG2 launches PLANETA Q

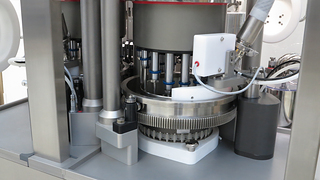

PLANETA is the MG2 best-selling continuous-motion capsule filling machine designed for medium and large productions. MG2 drive for innovation never stops and, even on this model of constant clear success, there is still, nevertheless, some room for improvement that the internal team of designers and the skilled technicians cannot miss.

By strengthening the PLANETA capsule filling machine qualities: from the modularity to the various weight controls that can be installed, from the user interface to ergonomics, an even more performing capsule filler has been conceived that, at the same time, can meet the specific needs of a new market niche: PLANETA Q.

Innovative design, great flexibility and ergonomics

The first novelty of PLANETA Q is the new design, which is the result of more than 50 years of MG2 experience in the development of capsule filling technology. In fact, a careful study of the operator-machine interaction has led to a more ergonomic design that allows total accessibility to the machine to carry out routine operations, whether they consist in either actual production or maintenance programs.

The machine edgy parts have been reduced and the internal layout has been conceived by focusing on ergonomics. The safety guards are “gull-wing”-shaped and the empty capsule selector SR/I is integrated into the machine, thus allowing for faster intervention by the operator. The control panel is mobile, which allows it to rotate around PLANETA Q at an angle of 180 degree, and it is equipped with a 21-inch touchscreen HMI developed ad hoc to make the control of every operation user-friendly. The VPN connection, then, allows faster remote access to ask for the online technical assistance. Connectivity is also enhanced thanks to the networking that has been designed for full integration with customers’ corporate network systems. With a production speed ranging from 6,000 to 100,000 capsules/hour and a complete coverage of the product range – from powder to pellets, from low dosages of powders to liquids, from tablets to microtablets – for both pharmaceutical and nutraceutical products, PLANETA Q summarizes the leading features of MG2 high technology which is now a standard for its customers all over the world.

Talking about flexibility, it is also possible to combine multiple products inside the same capsule thanks to two dosing units fitted in the machine. The net weight control is guaranteed, then, by the great performance of the MG2 patented weight control systems, which comply with the highest quality control standards required by customers.

OEB4 containment level

PLANETA Q, unlike PLANETA, offers high-level containment standards. The machine, thanks to its innovative design, complies with he OEB4 level, by ensuring maximum safety for both the operator and the environment, even while handling high-risk pharmaceutical products.

PLANETA Q is indeed equipped with gloves for safe access to the production area, special seals for the isolation of the operational area from the technical area, suction lances for dry cleaning and wetting guns. Finally, there is the possibility of integrating the machine with state-of-the-art protection devices, such as high-containment valves for product introduction and continuous liner for sample collection. PLANETA Q is already available at the MG2 showroom located at the production plant in Pianoro.

Read the article on Rassegna dell’Imballaggio International Issue

Prodotti e tecnologie: MG2

Gallery