P.E. & Spumador sign a success story

A partnership was sealed 40 years ago, and enhanced with collaborative and continuous innovation. P.E.Labellers & Spumador – Refresco group tell a success story.

When goals are combined, results are achieved faster and more effectively than the others. Here lies the secret of an authentic collaboration that focuses entirely on the common and important benefits and achievements to be reaped. This is the story conveyed by P. E. Labellers and Spumador, two companies that have made the history of Mineral Waters and beverage, and continue today to lead the international markets with strength and vision.

Spumador and Recoaro are part of the Refresco group, which is the largest companyon a global levelin the third-party production of soft drinks, fruit juices and mineral waters. Today Refresco is positioned as the world’s largest independent bottler, with 60 factories in Europe and North America. Recoaro mineral water represents a product to be enhanced not only in substance, but also in shape, with bottles of various sizes and materials, to be “confectioned” in the best possible way. Then the meeting came about with P.E.Labellers, a historic Italian companyactive for almost 50 yearsin the production of automatic labeling machines.

Spumador and P.E. Labellers: history of a partnership

“The partnership story with PE has lasted for more than 40 years – explains Tullio Tiozzo, the company’s Manufacturing Director. – The collaboration was born in the 1980s, when we felt the need to rely on a flexible and innovative supplier that could guarantee excellent after-sales service. This made the difference in the choice compared to other labeling companies. I have known Bruno Negri, Senior VP of P.E. Labellers, since then, and today I can say that our companies have had a very similar development, targeting more on innovation which the markets demand year after year. This way of doing business has rewarded both our companies, making them today a point of reference in their sectors”.

This relationship has evolved over time, with respect and mutual knowledge.

“We are proud to play an important role in the Recoaro production chain – confirms Bruno Negri. – For us, listening to customer needs and meeting every production requirement have proven to be the most successful factors over the years. Even before being a winning business strategy, it’s the PE philosophy, our DNA”.

Demands of the past and present

In the Recoaro factory’s two-year period 2019-2020, two PE machines were installed on the two PET lines with excellent results that were seen immediately. But how have the needs of the company changed over time? “With respect to the past, today we serve more flexible machines and with fast format change overs, given that the market requires continued developments both in the shapes of the bottles the eyes of consumers – says Tiozzo. – Modular machines are the correct answer to current needs. Today, in order to meet the challenges posed by an increasingly competitive market, we must continue to invest in new technologies, to enable the raising of the standards of productivity and reduce production costs. It is very important that the costs of maintenance of the machines installed are increasingly limited, and consequently, the most far-sighted choices will select partners that meet these needs”.

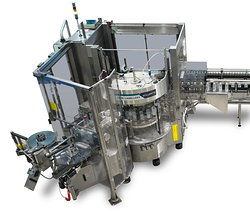

Recoaro recently installed a new P.E. machine on the PET mineral water line, with the primary objective of replacing paper labels with plastic ones and increasing the overall efficiency of the line. “The requirements requested were clear, challenging and satisfied at best – said Negri. – The machine had to be made with market components, proposed format changes interchangeable with the other two installed on an equal number of production lines, and the guarantee of a low annual maintenance cost. We understood the production needs of Recoaro: the customer’s challenge has become ours, and we have achieved joint success”.

The results expected and new goals

In Recoaro, business travels at high speed and safely. The new machine installed should produce 30,000 Bt/h in OPP with 4 different formats, relying on the care that P.E. pays to every step, assembly and installation, and testing and maintenance on all the formats. The objectives to be achieved are ambitious and manifold: to increase the productivity and flexibility of the line, replace the paper label with plastic and, in the medium to long term, increase efficiency with a decrease in maintenance costs.

What to expect from the future and how to equip yourself to move in advance? “The macroeconomic dimension that is outlined for the future inevitably suffers from the negative effects brought by Covid-19 – says Tiozzo. – The scenario that we can foresee sees the concentration of the number of players in all sectors, due to a takeover policy implemented by large groups. Only those who will be quick in innovating and interpreting the increasingly sudden changes expressed by the market will overcome the complex challenge that lies ahead”.

Recoaro chooses to set up strong and rewarding actions to consolidate its market share and acquire new ones. Refresco Italia is anticipating and aiming for new markets to conquer, such as that of copacking in the hard seltzer alcohol sector, and planning future investments to the benefit of current customers. New horizons will be addressed with the support of historical partners, such as P.E. that will be called to new challenges.

Read the article on Rassegna dell’Imballaggio International Issue

Gallery