The IMA Group at Pack Expo Las Vegas 2025

From 29 September to 1 October, the IMA Group will join Pack Expo Las Vegas, the largest packaging and processing show of 2025. Visitors will have the chance to meet the experts from the IMA Group, at the West Hall - Booth W-2144, that will be presenting the vision and innovations in the technological, digital and sustainable fields.

Pack Expo Las Vegas will be an opportunity to show the IMA Group's vision and innovations in the technological, digital and sustainable fields, and to explore them in a completely renewed and environmentally friendly stand.

Visitors will have the chance to meet the experts from the IMA Group, world leader in the design and manufacture of automatic processing and packaging machines, that will be presenting their latest technologies and developments.

Here are the machines and lines on show:

IMA PHARMA

SWIPE, labelling machine for vials, ampoules and cartridges: a natural gesture and a true natural for excellent labelling performance

Nothing could be closer to the truth than this statement. This new labelling solution is a leap forward into tomorrow. Boasting speeds of up to 800 containers per minute, labelled with unrivalled accuracy, SWIPE is also the ultimate in terms of flexibility. The latest labelling machine from IMA Life applies labels to vials, cartridges and ampoules using a positive transport system for maximum precision.

Modular and compact, the machine can be configured as an in-line solution or stand-alone. SWIPE also meets regulatory requirements according to GMP guidelines and is designed in view of a complete Track & Trace process.

Ergonomics and user-friendliness have taken on as much importance as performance with SWIPE. A balcony-style frame allows for side-mounted reel changes, and the support arm for the HMI and, when present, the vision system display can also be moved to facilitate operator access. Cleaning and maintenance operations are easily handled, and tool-free format changes enable swift operations keeping production agile and efficient.

Whether you are using paper or plastic labels, and regardless of container type, SWIPE ensures accuracy and speed. Significant configuration freedom lets you opt for a simplified setup to optimise cost and layout efficiency. Adapting to your needs rather than limiting your performance, SWIPE is swift, built for today and ready for tomorrow.

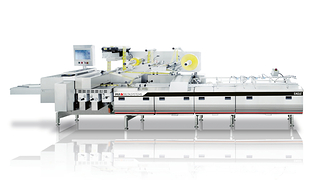

UNILINE, fast track your counting system

UNILINE is a conveying, filling and capping system that flexibly integrates the functions required to form a complete counting line: container loading, desiccant insertion, counting and filling, cotton insertion, capping, rejection.

Designed for maximum flexibility with no product or bottle change parts, UNILINE can be changed over very quickly and start up immediately at production speed for high OEE even when running small batches. The balcony design provides easy cleanability and visibility with no hidden entrapment points.

With UNILINE the highest level of count accuracy is granted by different counting technologies solutions available (Optical sensor and E.F.S. - Electronical field sensor) which are able to work also in difficult conditions.

Complete, fast, easy to use: Comadis C1290 tube filler

C1290 is a major update of the successful “C1090”, the benchmark model sold worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations.

Available in different levels of automation along with the widest range of additional devices, to grant the “state of the art” of single nozzle technology. Performance is combined to simplicity in change-over sequences and quick dismantling of contact parts.

FOOD & DAIRY

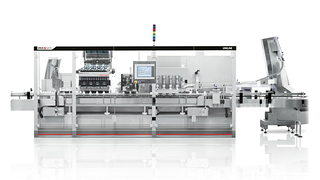

IMA Delta Systems Road Runner and Eagle

Fully automated row removal - Road Runner - and flow wrapping system - Eagle - manufactured in the United States and suitable for bars, cakes, pastries or other products that are delivered in an organized manner from process.

The Road Runner is an advanced row removal system that ensures smooth, continuous product transfer to the packaging line. Designed for precision at high speeds, it optimizes spacing and flow, reducing bottlenecks and boosting overall efficiency.

Directly feeding into the Eagle Series flow wrapper, this high-performance platform can exceed 1,200 packs per minute. Engineered for 24/7 operation, the Eagle ensures consistent, high-quality wrapping with maximum reliability and minimal downtime.

Vegatronic 6000 DZ - Continuous VFFS Vertical bagger

High-speed continuous motion vertical bagger with fully automatic format change and unmatched pack style flexibility

The IMA Ilapak Vegatronic 6000 DZ is a continuous motion vertical bagger designed to deliver high-speed performance and exceptional pack style versatility. Ideal for demanding packaging environments, this model is engineered to run shredded cheese, pet food (including flakes, pellets, and accessories), confectionery and chocolate (as loose products), as well as snacks and biscuits. Its compact footprint, full-servo design, and automatic format changeover make it a flexible and efficient solution for producers seeking premium presentation and fast changeovers across a wide range of pack styles - including Doy, Quad seal, Pillow, and 3-side seal bags, with or without zippers.

The Vegatronic 6000 DZ features interchangeable components with other Vegatronic 6000 models, including forming sets, jaws, belts, and consumables - reducing spare part inventory and lifecycle costs.

Its rotated jaw carriage, ideal for Doy Shark and 3SS formats, can be installed or removed with minimal effort thanks to a dedicated cart system. Whether starting with simple pillow packs or scaling up to premium reclosable pouches, the Vegatronic 6000 DZ offers a future-proof solution with unmatched flexibility and efficiency.

Delta 3000 - M.A.P. Flow wrapper

Flow wrapping machine with long dwell technology for hermetic sealing and M.A.P (Modified Atmosphere Packaging) applications

The IMA Ilapak Delta 3000 is a horizontal flow wrapping machine designed to meet the highest standards in hermetic sealing and Modified Atmosphere Packaging (M.A.P.). Equipped with long dwell sealing jaws and advanced PC control, it guarantees outstanding performance on a wide range of recyclable wrapping materials - even under high-speed production requirements.

Robust, reliable, and highly versatile, the Delta 3000 is ideal for products requiring extended shelf life such us, fresh and processed meat (sausages, minced meat, burgers), sliced or portioned cheese, bakery products in M.A.P. and ready meals. Its modular design allows easy integration into automated lines.

IMA E-COMMERCE

The IMA E-COMMERCE division will showcase a complete E-Fulfillment line in action, from case forming to closing, together with its exclusive partner for North America IPG - Intertape Polymer Group.

Experience the E-CO Flex XL Forming up close: a case erector designed to handle multi-size FEFCO 201 and FEFCO 200 cases, compatible with both single- and double-wall cardboard. This machine is tailor-made for the Intralogistics sector, where box dimensions are significantly larger than those typically used in E-Commerce fulfillment.

Don’t miss the E-CO Flex SealMatic: a fully automatic, random case closer engineered for FEFCO 201 and SIOC containers. It features an automatic bypass and applies sustainable water-activated (WAT) tape, processing up to 20 boxes per minute.

Prodotti e tecnologie: IMA-INDUSTRIA MACCHINE AUTOMATICHE

Gallery